Only Mine

Gourmet chocolate manufacturer.

View case study

Gain full visibility of your production processes, costs, and outputs with Supply'd’s production management solution. Easily schedule runs, define production stages, and create custom recipes and yields for each product. Track batches and labour at every step to inform accurate costing, and use finished items within other production recipes for greater versatility. With batch labels, custom fields, and a clear snapshot of final costs and margins, Supply'd production management software equips you with the insight and control you need to refine and optimise your production strategy.

Powered by Supply'd Intelligence

Powered by Supply'd Intelligence

Smart Production Planning uses Supply'd Intelligence to automatically generate a production schedule based on your preferred planning method. It can take into account delivery dates from sales orders, minimum stock holds, current stock levels and forecasted demand to ensure you're always producing the right products at the right time. It even factors in required sub-recipes, giving you a complete, end-to-end production plan without the manual guesswork.

Break down a single input into multiple outputs with Supply'd’s production breakdown feature. Built for butchers, extractors, and bulk processors, it lets you manage carcase splits, ingredient yields, and by-products with precision. Track all resulting items — from cuts and trim to oils, cakes, and waste — while automatically calculating yields, losses, labour, and batch costs. With full traceability and clear margin visibility, Supply'd production management software helps you minimise waste and maximise the value of every input.

Keep all your product recipes organised in one place with Supply'd production management software. Define specific production stages, list components such as ingredients, packaging, or other items, and let automatic costing calculate recipe costs using your current buy prices. Recipe pricing is automatically updated as component costs change. Generate professional recipe and costing PDFs in seconds.

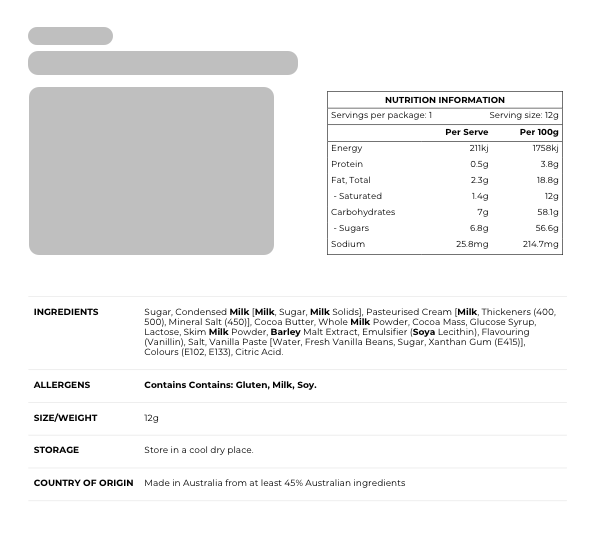

Track key food-specific details such as nutritional tables, ingredients, allergens, country of origin, shelf life, and storage types, while automatically syncing product information with third-party sales channels. Build kitchen and production recipes, generating ingredient lists, allergens, percentage Australian content, and nutritional tables directly from recipes. Supply'd production management software also enables you to generate compliant labels, recipe cards, and product sheets, with allergens clearly highlighted, while uploading spec sheets and certificates to streamline your HACCP compliance.

Powered by Supply'd Intelligence

Powered by Supply'd Intelligence

Be ready for the unexpected with Supply'd’s intelligent recall traceability. With one click, Supply'd Intelligence identifies every production run and sales order linked to a specific batch—so you can isolate affected stock, write it off, and notify customers instantly. Whether it’s a faulty ingredient or a contamination issue, you can act fast, stay compliant, and protect your customers and your brand.

Discover a transformative production management system designed to simplify and streamline even the most complex business challenges, empowering you to operate with greater clarity and efficiency.

Book a demoSupply'd production management software leverages our extensive expertise in the food and retail industries, combining it with cutting-edge technology to drive innovation.

Our difference lies not only in what we offer but in how we approach the needs of food and retail businesses. We combine innovative technology with deep industry understanding to create tailored production management software solutions that drive measurable impact.

Supply'd eliminates the need for multiple plug-ins or additional systems by offering a comprehensive, end-to-end platform tailored to the food and retail sectors. This streamlined approach reduces production management inefficiencies, manual workarounds, and complexity.

Unlike alternative production management solutions with self-managed or automated support models, Supply'd provides responsive, human-centric customer service. You have direct access to decision-makers and proactive assistance, fostering trust and ensuring smooth implementation and ongoing success.

Supply'd is specifically designed for food and retail businesses, addressing your unique production management needs. Its industry-specific features and insights deliver practical solutions where generic systems fall short.

Supply'd uses cutting-edge technology, avoiding the “old-school” limitations of some competitors. The production management system grows seamlessly with you, offering scalability without requiring additional systems or major disruptions.

Supply'd is a specialised Food ERP System designed to replace spreadsheets and generic accounting add-ons. We combine manufacturing, warehousing, sales, and logistics into a single source of truth.

Supply'd Intelligence is the engine behind your smartest decisions—designed specifically for food & retail businesses. It forecasts demand, predicts sales and production needs, and powers automation across purchasing, invoicing, and delivery. Your data remains private and secure, with insights tailored exclusively to your business. Discover a smarter way to operate, driven by your data.

Learn moreYes. Our Smart Production Planner automatically calculates what needs to be made based on current stock, minimum stock levels, and incoming sales orders. It generates a clear daily schedule for your team, so they know exactly what to prep, cook, and pack.

Yes. You can build complex Bill of Materials (BOM) with unlimited nesting. Create a "Sauce" batch, then use that sauce as an ingredient in a "Ready Meal" batch. Costs, allergens, and batch numbers flow through every stage automatically.

Yes. You don't need to do the math manually. Enter your target quantity (e.g. "500 units"), and the system automatically scales the entire recipe for that run.

Staff use tablets or scanners to record ingredients as they are added to the mixer/kettle. This creates a digital Batch Record, linking the specific ingredient batches (e.g. flour bag #123) to the finished product for 100% traceability.

Yes. As soon as a batch is produced, you can print Finished Goods Labels (with batch codes, expiry dates, and batch QR code) directly to a wireless printer. This ensures stock is labelled correctly before it even hits the warehouse.

Yes. Our Item Breakdown feature allows you to take one input (e.g., a Side of Beef) and break it into multiple outputs (Steaks, Mince, Trim), allocating costs and weights to each cut accurately.

Yes. Supply'd uses live inventory data. If the buy price of flour increases on a Purchase Order, your Recipe Costs and margins are recalculated instantly, so you never sell at a loss without knowing it.

Yes. Labour is often your biggest cost. Supply'd allows you to track Labour Hours to specific production runs. This gives you a "True Cost of Goods" that includes ingredients, packaging, and the team's time, so you know your exact margin on every unit.

Absolutely. Supply'd tracks what you should have used versus what you actually used. This highlights Yield Variance, helping you spot wastage, over-portioning, or theft in the production line.

Stuff happens. Staff can log actual yields (versus expected), and allows them to record notes for the variance for future reference. This removes the stock from inventory and records the cost against the batch, keeping your inventory and financials accurate.